Ceramic Coating a Brand New Chevy Corvette: Step-by-Step Process

Hey, it’s Andy with Mid-MO Dents! Today, we’re working on a brand-new Chevy Corvette, and we’re going to apply a 5-year ceramic coating. This Corvette only has a couple hundred miles on it, but we’ll still take you through the prep and coating process, making sure everything looks flawless. Stick around, and let us know if you have any questions!

Prepping the Corvette

We pulled the Corvette into the shop to check it over before starting the ceramic coating process. Since the customer lives on a gravel road, there was a fair amount of dirt and mud in the inner fenders and on the wheels. We began by hitting the problem areas with a degreaser to break down the road grime, focusing on the wheels, tires, inner fenders, and lower parts of the body.

After pre-rinsing the vehicle, we used a soap that contains no waxes or temporary protection to clean the paint thoroughly. This is a critical step because any leftover wax or oils can interfere with the ceramic coating, which is a semi-permanent protection layer. We guarantee this particular 5-year ceramic coating on all exterior surfaces, including paint, plastic, windows, wheels, and chrome.

Cleaning the Wheels

After rinsing the vehicle, we turned our attention to the wheels. We always clean the wheels last before rinsing out our mitts. For this job, we used Adam’s Polishes wheel brush to scrub the wheel faces and barrels, making sure everything was spotless before moving on.

Air Drying and Prepping for Coating

Once the vehicle was clean, we used compressed air to dry every crack and crevice. With professional-grade ceramic coatings like ours, water left on the vehicle can cause issues if it drips down during the coating process, hardening the ceramic and creating an unsightly mess. That’s why we spend extra time blowing out every nook and cranny, including the engine bay and door jams.

We then used a coating prep spray to ensure the surface was ready for the ceramic application. This spray helps remove any possible waxes, polishing oils, or contaminants, though the paint on this brand-new Corvette was in great shape without any noticeable swirls or scratches.

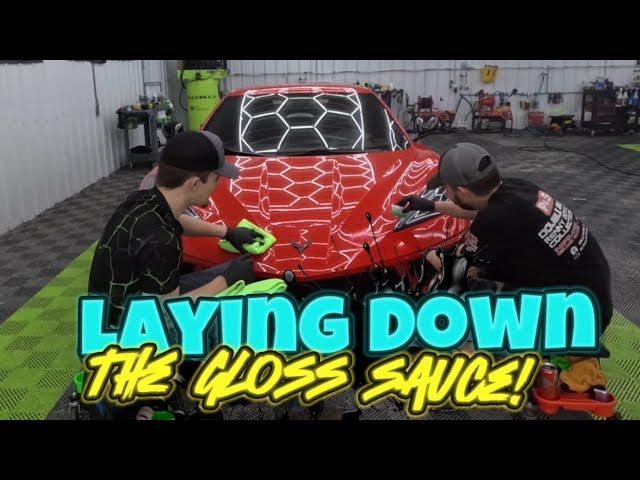

Applying the Ceramic Coating

With the prep work complete, it was time to start applying the 5-year ceramic coating. We coated all the exterior paint, plastic, windows, wheels, and chrome using a professional-grade coating. If you're a detailer or a customer considering doing ceramic coating yourself, it’s important to use high-quality products, even if they aren’t the cheapest. The harder and more durable the coating is, the longer it will last.

We use a three-towel method to level the coating, ensuring it’s applied evenly without leaving any high spots. The first towel removes most of the excess coating, the second picks up the finer residue, and the third towel is for good measure, preventing any uneven areas.

Each section requires about two minutes to set before we start leveling the coating. We follow the manufacturer's instructions carefully to guarantee a lasting finish.

Coating the Wheels and Windows

After finishing the paint, we moved on to the wheels. We typically only coat the wheel faces unless the customer requests the barrels be coated as well. Next, we applied ceramic coating to the windows. While ceramic coating on glass doesn’t last as long as it does on paint, it still provides solid protection for several years.

Tire Coating

To finish the job, we applied a tire coating called Tough Shine, which lasts for about a year. Unlike many other tire coatings, this one doesn’t make the tires look overly glossy or attract dust and dirt, making it perfect for vehicles that see a lot of gravel or dirt roads. It’s a product we’ve recently started offering, and both we and our customers have been really happy with the results.

Wrapping Up

After everything was coated, we left the Corvette inside overnight to let the coating cure for 12 hours. Tomorrow, we’ll come back for part two and finish up by tinting the windows.