Jeep Gladiator Ceramic Coating: Full Process Breakdown

Hey, it’s Andy with Mid-MO Dents! Today, we’re working on a Jeep Gladiator that’s in for a full ceramic coating. The customer bought this vehicle used, and it had a few light scratches and swirls that needed to be corrected before we could apply the coating. We’ll walk you through the entire process, from cleaning and prepping to the final ceramic coating. Let’s dive in!

Pre-Wash and Degreasing

We began by giving the Jeep a thorough inspection. Although it was relatively clean, the customer knew the paint needed some extra work to remove minor scratches and swirls. The tires also had some old dressing and dirt buildup, which gave them a dingy appearance. First, we cleaned the engine bay while applying a degreaser to the tires, agitating the grime with a brush to loosen all the built-up dirt.

Next, we moved to the front of the Jeep to degrease the grill, bumper, inner fenders, and lower doors, where road film and debris tend to accumulate. We also degreased the bed of the Gladiator, using a pressure washer equipped with a low-pressure tip to safely clean the engine and other sensitive areas without risking damage to the paint.

Foam Washing

After degreasing, we moved on to foam washing using Griot’s Garage foam cannon and Dirt Buster soap. Once the Jeep was covered in foam, we scrubbed down the entire body to remove any remaining dirt and grime. Foam washing is a key step in the cleaning process, as it helps lift dirt from the surface and ensures a thorough clean before we move on to the next steps.

Clay bar Treatment

With the Jeep now clean, we rinsed off all the soap and started the clay bar process. Clay barring is essential for removing any embedded contaminants like brake dust, overspray, or tree sap that regular washing can’t reach. This step leaves the paint feeling silky smooth, providing the perfect surface for polishing. It also prevents contaminants from getting caught in the buffing pads during polishing, which helps avoid creating more swirls.

Drying and Paint Inspection

Once the clay bar treatment was complete, we began drying the vehicle. Starting with a shammy to remove the bulk of the water, we then used compressed air to blow out any moisture trapped in the cracks and crevices. This ensures that no water is left behind, which is especially important before ceramic coating, as moisture can interfere with the application.

Next, we inspected the paint under a correction light. The light revealed the light swirls and scratches the customer wanted removed. Before polishing, we masked off all the plastic trim to prevent any buffing compound from staining the surfaces.

Paint Correction

With everything prepped, we performed a small test spot using a RUPES yellow pad and Sonax 04-06 polish to ensure we had the right combination for the job. Once we confirmed the right setup, a couple more team members jumped in to help polish the entire Jeep, working methodically to remove the imperfections in the paint.

Tire Coating and Final Prep

While the paint correction was underway, we took the time to clean the wheels and apply a tire coating. This not only restored the tires to their proper appearance but also provided lasting protection against dirt and grime.

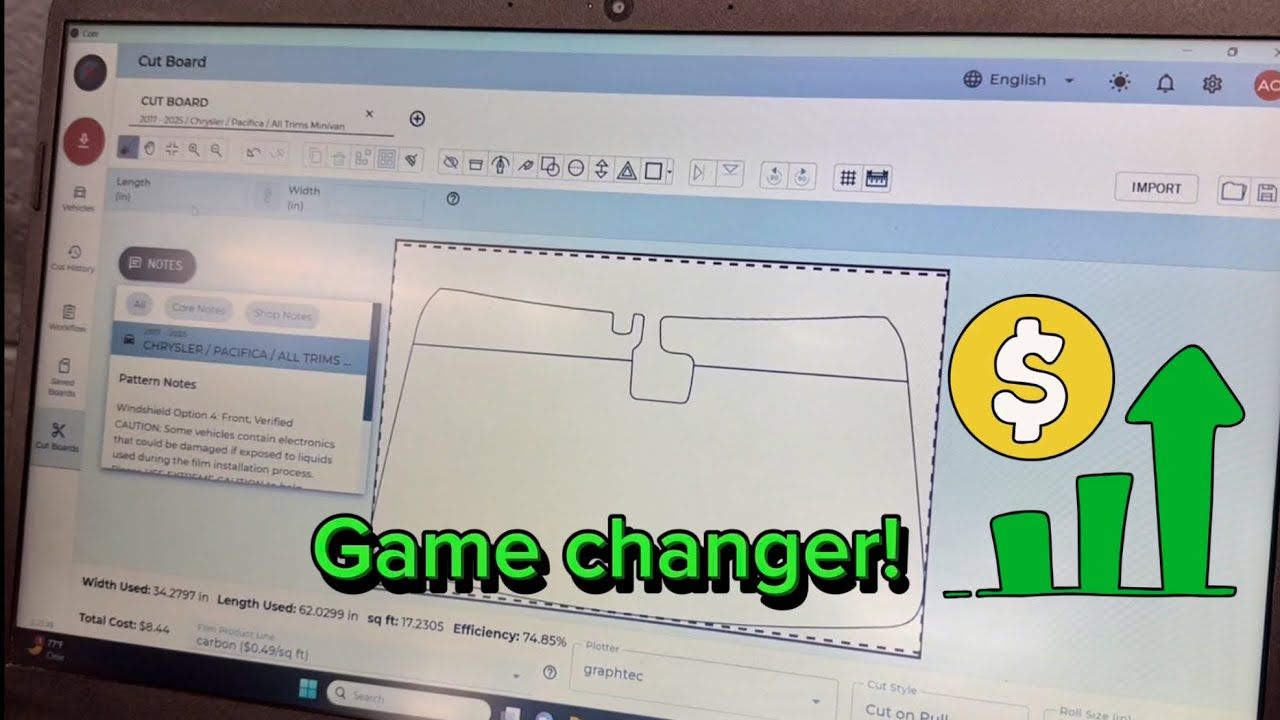

Before starting the ceramic coating, we blew out the cracks and crevices one final time to ensure no water or dust was left behind. Then, we applied a panel prep spray to the paint, wheels, and windows, which cleans the surfaces of any oils or residues left from the polishing process, ensuring the ceramic coating bonds properly.

Ceramic Coating Application

Now for the main event—the ceramic coating. We carefully applied the coating to every surface of the Jeep, including the paint, plastic trim, windows, wheels, and even chrome accents. The process requires precision and patience to ensure a perfect, even finish. Once applied, the ceramic coating will provide long-lasting protection, making the vehicle easier to clean and keeping it looking great for years to come.

Final Look

With the ceramic coating fully applied and cured, the Jeep Gladiator looked incredible. The glossy finish not only enhanced the appearance but also provided a durable protective layer across all surfaces.